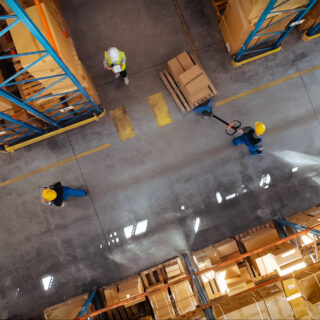

Interconnect your ERP with your company's vertical warehouses

We support companies from a wide variety of industries in integrating their ERP with the most popular vertical warehouses on the domestic and international market. We strongly believe in the business benefits of integrating the software and the vertical warehouse, and we have evidence of this every day as we see the steady growth of our customers.

One of the great advantages of adopting an automated vertical warehouse is the interaction with ERP management software. The dialogue between ERP and the automated vertical warehouse provides companies with a number of benefits, including speeding up the procurement process and minimizing the risk of misalignment between the physical warehouse and the virtual warehouse.

The software made by BTW allows the generation of a pick list (or picking list) for each requested movement, the pick list is automatically acquired by the automatic vertical warehouse software and generates, under the supervision of an operator, the movement of the material.

The material being handled is, therefore, made available to the operator who can arrange for delivery.

The outcome of the operation is transmitted to the management system.

Contact us