Energy control: the solution to reduce costs, maximize productivity and improve energy efficiency

At a time in history when bills are every business owner’s nightmare. consuming better and spending less is possible. In the Smart Factory, it is now essential to reduce energy costs and associate them with production batches; in fact, the key words are energy efficiency, integration to existing software, and environmental sustainability.

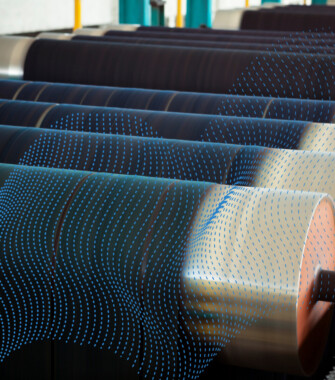

Sensors: monitor and analyze energy consumption

The first step in achieving satisfactory energy efficiency is to integrate wireless sensors to the manufacturing plant that can detect, monitor, and analyze energy consumption. The sensors are self-powered, installation does not require downtime and maintenance also enable:

-

Analyze and verify energy performance down to the individual device

-

Verify the correctness of the consumption attributed in the bills

-

rationally allocate energy consumption

Contact us

Connect ERP to the environment

The graphical tools for analyzing and monitoring energy consumption made available make it possible to clearly see how much, how and where energy is used and correlate it with production parameters. To complete the solution, we developed SI-GREEN CONNECTOR, which allows the information collected from the sensors to be transferred directly into the ERP in use in the company. Theintegration between sensors and ERP brings with it several benefits that improve the marginality of each production batch:

-

Identify how much energy is consumed for each batch produced

-

generate comprehensive energy cost estimates

The strategy toward sustainability

Being a sustainable company is no longer a choice: with the Fit For 55 legislation, the European Union has a legal obligation to reduce emissions by at least 55 percent by 2030. To help manufacturing companies meet the required legislative requirements, we have developed dedicated services:

-

Assessment and data collection that enables mapping of the production facility

-

Analysis with supporting documentation to bring out energy deficits, waste , and time slots when energy is most used

-

proposal for an efficiency plan

-

Periodic maintenance checks and coupons that allow theproduction plant to remain high-performing and sustainable at the same time