Why choose ADeMES?

ADeMES is very mportant for the 4.0 transition and is much more than just a simple MES because it enables computerisation of production processes and improves performance.

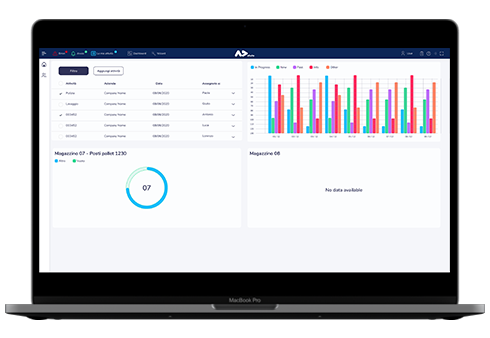

ADeMES generates the production times for each order, digitally provides the production specifications, monitors the progress of the work, plan workers’activities and manages non-conformities, all in a coordinated manner between all the various departments of the company, from production to management, via the technical department and the warehouse. In fact, ADeMES can also include ADeWMS (Warehouse Management System), the warehouse management software.

Made entirely by Trizeta, ADeMES is the right tool for companies that want a production management and control information system:

In cloud

Available in the cloud

(public, private, on premise)

Simple

Quick and easy to learn and use

Customizable

Customizable and connectable with corporate ERP

What does our MES give you the most?

- PRODUCTION: All production activities are carried out from any device with a Chrome browser, including from smartphones and tablets placed in a totem or near the processing machine.

- WORK SPECIFICATIONS: ADeMES enables production management by eliminating paper documents previously essential to perform tasks, such as data sheets, material and equipment use reports, and vehicle sheet management.

- PROCESS DATA COLLECTION: ADeMES offers multiple ways to collect production data, both of operator and machine times and quantities of semi-finished or finished products. Different counting modes to suit the needs of the company.

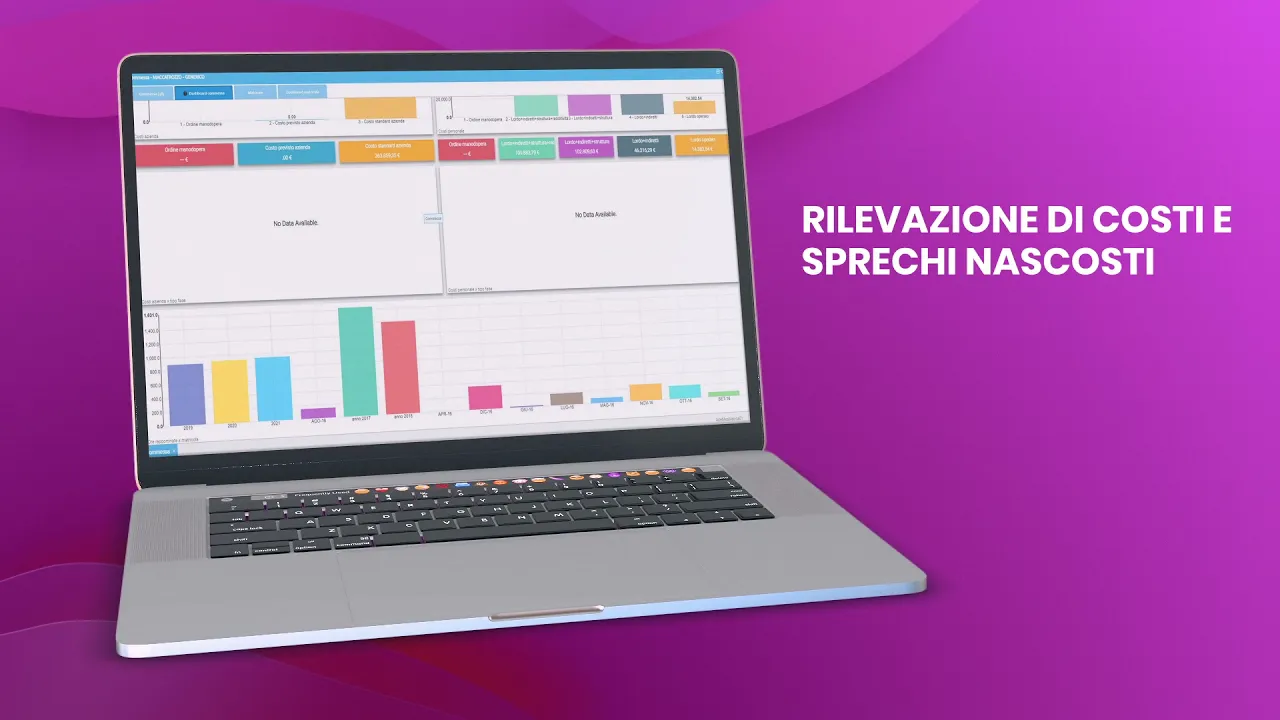

- DEFINITION OF COSTS AND STATISTICS: ADeMES has as its primary objective the valorization of measured costs: machine, operator and material costs. A precise facet of costing for accurate production controlling.

- MANAGING, CONTROLLING AND OPTIMIZING ACTIVITIES: ADeMES not only counts finished product, it also allows you to make deposits by pallet or unit load, unload raw materials when they are loaded into the machine, and manage the customer’s signature at the delivery and installation stages.

- INTEGRATIONS AND INTERCONNECTIONS: ADeMES can connect to the ERP present in the company with a bidirectional dialogue so as to extend functionality, including providing for real-time office and production information exchange functions.

Integrations

ETL technology of interconnection with ERP

The maximum and total real-time integrability of production data from ADeMES with enterprise ERP systems enables the manager to be more proactive in how he or she plans production, manages raw materials and components, and optimizes machines.

ADeMES is already integrated with major ERPs such as: Zucchetti -AHR – Infinity – Fluentis – Arca EVolution – Onda – Navision – Sap R3 – Sap business one

All trademarks mentioned are the property of their rightful owners

Preconfigured modules for connection to MACHINES 4.0

The connection of ADeMES to facilities, transmission protocols and enterprise information systems was developed through a modular system that allows a new machine to be connected through the development of the module that implements the specific communication protocol.

OPC UA MT-CONNECT more

Integration with scheduling software

ADeMES, in addition to ERP interface for production orders, is capable of receiving planning and scheduling information from the main software on the market, automatically allowing the creation of the calendar for the execution of processing steps.

The information flows through the entire corporate structure, from production to the engineering department to the director’s smartphone or tablet.

Contact us

Production

- ▪ Intuitive touchscreen graphical user interface, on PC, tablet or

- smartphone

- ▪ Data entry in a few quick steps

- ▪ Activities organized by calendar or job order, interfaced with the

- management system or ERP

- ▪ Access to technical drawings and production data

- ▪ Communication via chat with the technical office

- ▪ Management of non-conformities, downtime and waste of

- production

- ▪ Verification and modification of the production bill of materials

Technical office

- ▪ Guaranteed accessibility from anywhere thanks to the development

- in HTML5

- ▪ Import of production orders from ERP and/or entry manual

- ▪ Monitoring production progress

- ▪ Scheduling of the activities of operators and machines in production

- ▪ Loading of processing specifications through:

- ◦ CAD or PDF technical drawings

- ◦ photographs taken directly from production

- ◦ technical data sheets detailing the products

- ◦ video tutorial of the processes

Operations Manager

- ▪ Verification of OEE (Overall Equipment Effectiveness, i.e. indicator

- effectiveness of the production plant) of machines and operator

- performance

- ▪ Visual access to the summary of all activities

- ▪ Data verification and production progress

- ▪ Waste monitoring in terms of rejects, errors, downtime

- ▪ Management of holiday and permit requests sent by operators

- through ADeMES